Plastic Box Strapping is another important part of Plastic Extrusion Machineries. This Box Strapping are Manufactured from Either Polypropylene (PP )/High Density Polyethylene and Other is Polyethylene Terephthalate (PET) there are Different terms used in Industry Like Patti, Strap or Strapping. This Straps are mostly used in form of Packaging. Mostly the Strap for PP-HDPE is Manufactured from Recycle Plastics Granules or Pallets and PET Strap is made from 100 % Recycled PET Flakes. The Strap comes in Standard size of 9 MM, 12 MM, 16 MM and 19 MM. There are Two Kinds of Different Machine that is Supplied depending upon the Grade of the Plastic which has to be processed in order to Manufacture the Straps. Lets go through with PP- HDPE Box Strapping Extrusion, In this Grade there could supplied a Semi Automatic and Fully Automatic Machine.

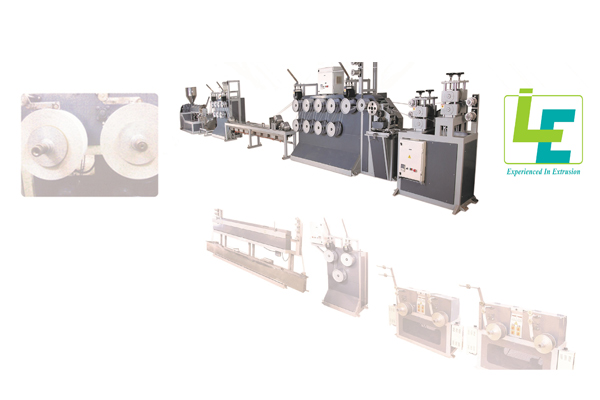

The Semi- Automatic Machine Strap are know as Heat Sealable Straps but the Winding in this Mechanism is Normal, However in Fully Automatic Machine the Straps are know as Fully Auto Strap which has got Fully Automatic Servo Based Winder. Addition to looking that Quality Expected in the Market an Attachment could be Provided, Which is Called as Jockey Extruder which allows to Coat a thin Layer of Virgin Melted Granules in order to get much Better shining on straps . The Machine has specially designed screw and barrel for processing re-process Granules to be processed, with Screen Changer for Filtration of the melted granules and 3 Godet Units for the Stretching the Straps .

Now the another Important Grade of Strap is Made from PET Flakes, Commonly Mentioned as PET Box Strapping. Pet Flakes is nothing but the Bottles which is made from Pet Grade is Hot Washed and turned in Flakes or in simple its Crushed into smaller pieces. The Important Function of Pet Box Strapping Extrusion is a Dehumidifier and Crystallizer. Here the Hot Washed Flakes are Feed into Dehumidifier which removes the Moisture and throws to a Crystallizer which heats up the Flakes and sends to the Hopper Loader of the Machine. For Pet Strap there is by Default a Jockey Extruder attached for applying the Master Batch Layer. This Machine is Equipped with 3 Godet units which has a heat rolls which is Attached with MTC in order to provide heat with Oil Circulation.

Box Strapping is used in various forms depending upon the nature of Packaging , Like PP- HDPE are used in Bundling News Papers, Corrugated Boxes to Intact , Packing of Glass or Metal Articles, Apart from this it’s used Packing of Ceramic Tiles and Not only that it is used Within Plastic Industry for Packing the Plastic Rolls , Woven Sack , Stretch Film Rolls, Plastic Pouches etc. Wherein PET Strap is used in Industry where the Weight of the Article is Above 500 Kgs, because it has got much better strength compare to PP –HDPE . Few Industry wherein PET is used are Reinforcing of Wooden Boxes, Bundling of concrete block , holding bales of agriculture products or textiles and in Attaching of Cotton.